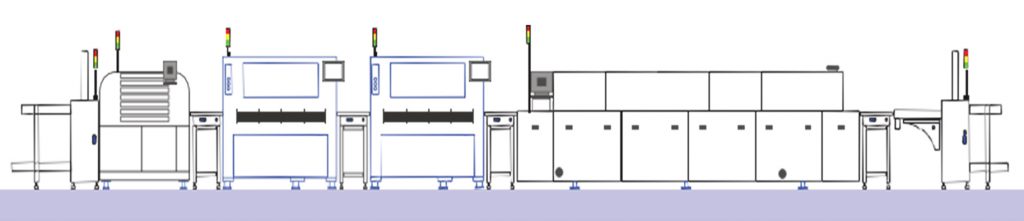

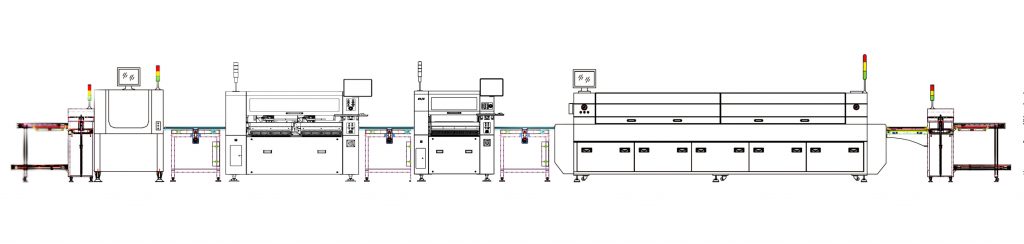

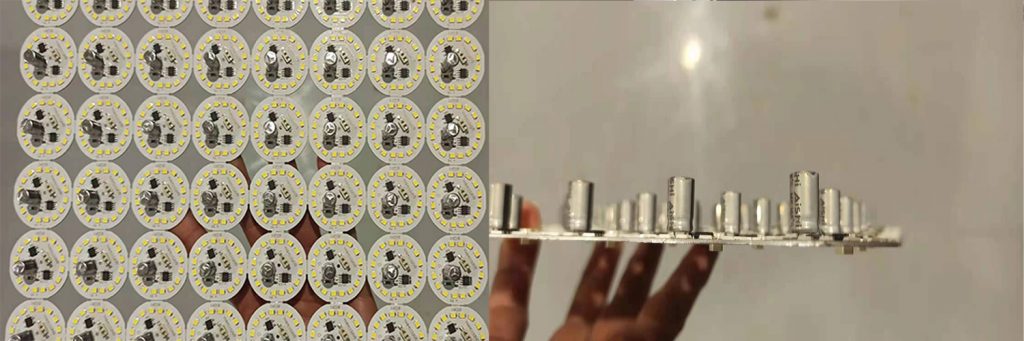

The general SMT production process includes Solder Paste Printing, Placement and Reflow Soldering three steps, so to invest a complete SMT production line, necessarily including the implementation of the above process steps of the equipment: printing machine, placement machine and reflow soldering oven. Especially the PnP machine, often accounting for more than 70% of the investment in the entire production line, so the choice of PnP machine is the most critical.

At present, there are many manufacturers brands of pick and place machines, but according to the scale and speed can be roughly divided into high-speed machine and mid-range machine, and others semi-auto small machine. The price of a large machine is generally three to four times than of a medium-sized machine. So the budget usually restrained, especially under the global economic waving like swing, but it is bring Chinese brands opportunities into fast developing in SMT industry but for customers it is still not a easy to confirm their final investment.

Let us share an investment:

Generally, a basic recommendation SMT pick and place line composed 2 mounters, one for Chips and other for ICs, so that each has its own responsibilities, which is conducive to the mounters to play the highest efficiency.

After few rounds of cost negotiations, customer finally picked our first recommendation, it is in other side to proved that a Chinese brand much clearer the range of a investment cost.

For this case please go to www.longtingsmt.com or www.longtingsmt.en.alibaba.com to learn LT8. Or contact at sales1@longtingsmt.com to sharing.

The investments always changing in different global environments, the SMT technology is the center of modern industry, for the pick and place machine require, the capacity is the first to consider, and then the specification depends on which of components need to be mounted on the board. When purchase a new pick and place machine from WENZHOU RONGTING TECHNOLOGY CO.,LTD. we need to know below first things as the start:

- What size of circuit board;

- How many difference components will be used;

- What types of components such as 0201, 0402…

- What the budget range.

By Jesse Hou

sales at sales1@longtingsmt.com